Biological Safety Cabinets safeguard users, materials and the environment from aerosol hazards and other types of environmental contamination.

Uses

They are utilized by a wide range of scientific, research and development organizations within both the commercial and non-commercial sectors, including pharmaceutical, medical, clinical research, defense, education and general healthcare sectors.

Classes and Characteristics of Biological Safety Cabinets

There are three classes of BSC: Class I, Class II and Class III. Selection of the proper class of BSC requires careful evaluation of the activities to be carried out. Laminar Flow Cabinets or other clean benches that direct air towards the operator are not biological safety cabinets and must not be used for handling infectious, toxic or sensitizing materials.

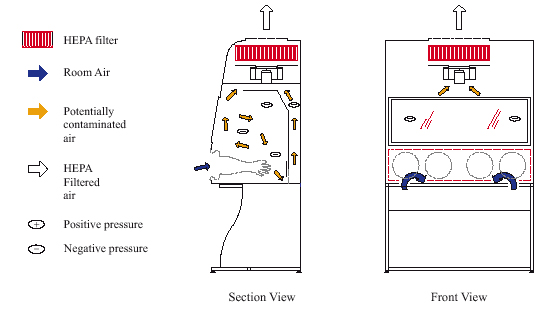

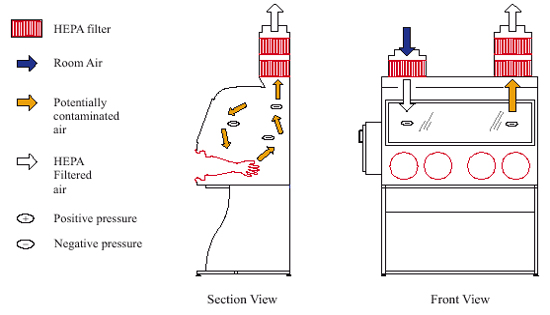

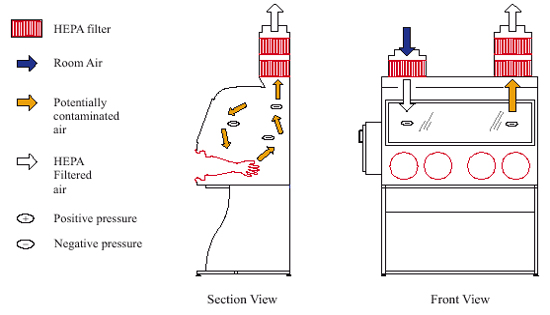

Class I Cabinets

These cabinets have non-recirculated airflow away from the operator that is discharged to the atmosphere after filtration through a HEPA filter. They provide good operator protection but do not protect the product within the cabinet from contamination.

Class II Cabinets

Class II cabinets are designed for personnel, product and environmental protection. They are designed for work involving microorganisms and are divided into two types (A and B) on the basis of construction type, airflow velocities and patterns, and exhaust systems(4).

Within type (A), there are two subtypes, A1 (formerly designated type A) and A2 (formerly designated type B3). Within type (B), there are two subtypes, B1 and B2. Class II cabinets are most commonly used in biomedical research laboratories because of their characteristics.

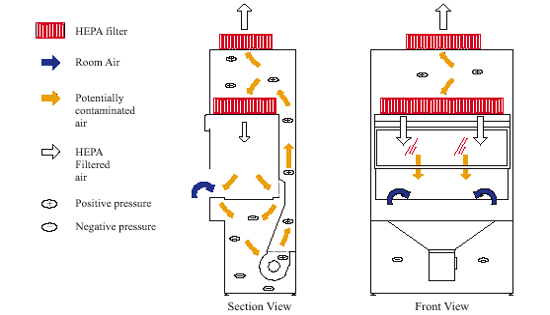

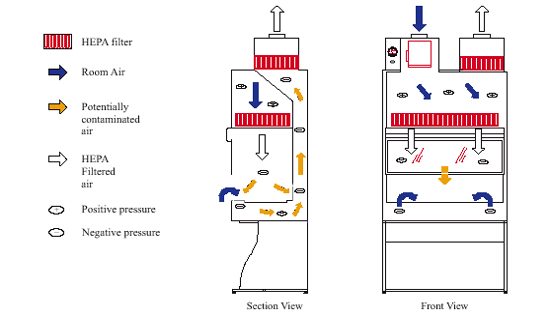

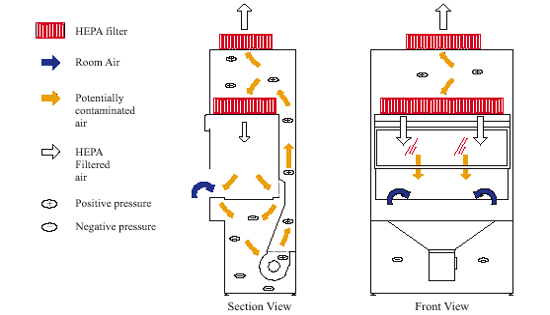

Class II, Type A1 Cabinets

- Cabinet air may be recirculate back into the laboratory or ducted out of the building by means of a "thimble" connection (i.e., a small opening around the cabinet exhaust filter housing) whereby the balance of the cabinet is not disturbed by fluctuations in the building exhaust system. The thimble must be designed to allow for proper certification of the cabinet (i.e., provide access to permit scan testing of the HEPA filter).

- Maintain a minimum average face velocity of 0.38 m/s (75 ft/min).

- May have positive pressure contaminated ducts and plenums.

- Are not suitable for work with low levels of volatile toxic chemicals and volatile radionuclide’s.

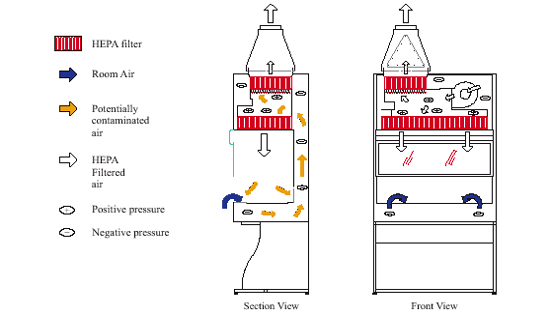

Class II, Type A2 Cabinets

- Cabinet air may be recirculate back into the laboratory or ducted out of the building by means of a "thimble" connection (i.e., a small opening around the cabinet exhaust filter housing) whereby the balance of the cabinet is not disturbed by fluctuations in the building exhaust system. The thimble must be designed to allow for proper certification of the cabinet (i.e., provide access to permit scan testing of the HEPA filter).

- Maintain a minimum average face velocity of 0.5 m/s (100 ft/min).

- Have ducts and plenums under negative pressure.

- Is suitable for work with minute quantities of volatile toxic chemicals and trace amounts of radionuclides.

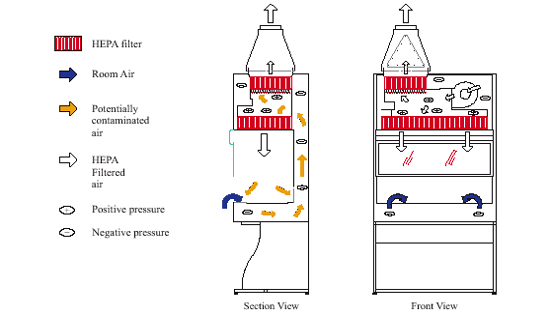

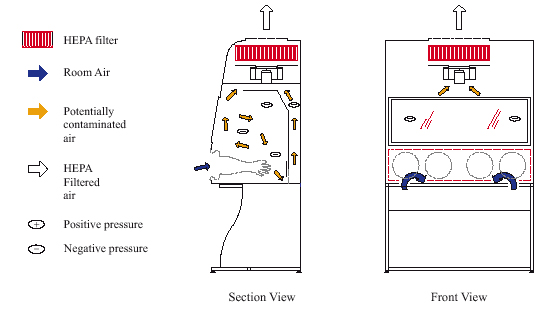

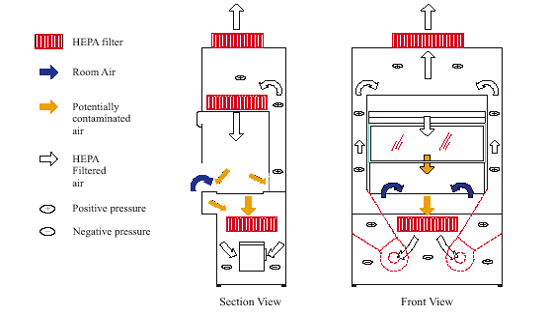

Class II, Type B1 Cabinets

- Hard-ducted through a dedicated duct exhausted to the atmosphere after passage through a HEPA filter; contain negative pressure plena.

- Maintain a minimum average face velocity of 0.5 m/s (100 ft/min).

- Recirculate 30% of the air within the cabinet.

- Suitable for work with low levels of volatile toxic chemicals and trace amounts of radionuclide.

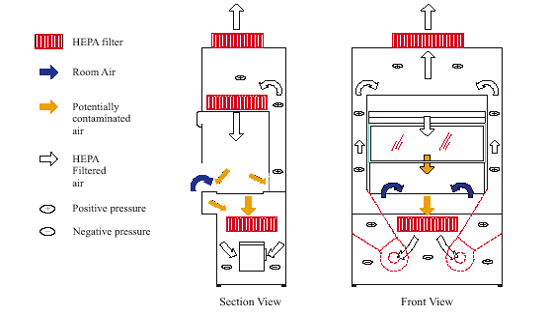

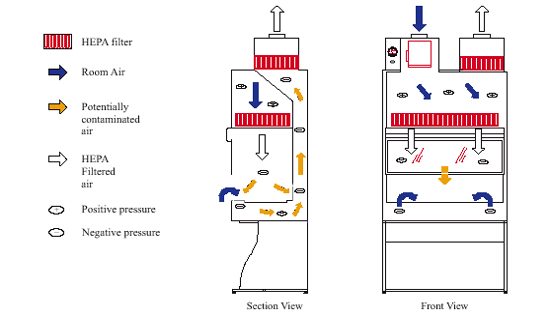

Class II, Type B2 Cabinets

- Does not recirculate air within the cabinet.

- Maintain a minimum average face velocity of 0.5 m/s (100 ft/min).

- Hard-ducted through a dedicated duct exhausted to the atmosphere, 100% of cabinet air, after passage through a HEPA filter; contain negative pressure plena.

- Suitable for work with volatile toxic chemicals and radionuclide’s.

Class III Cabinets

Class III cabinets are totally enclosed and gas-tight with HEPA filtered supply and exhaust air. Work is performed with attached long-sleeved gloves. The cabinet is kept under negative pressure of at least 120 Pa and airflow is maintained by a dedicated exterior exhaust system. Class III cabinets protect the worker and the product. The exhaust air is double HEPA filtered or treated by HEPA filter and incineration. Removal of materials from the cabinet must be through a dunk tank, double door autoclave or air-lock pass-through for decontamination.

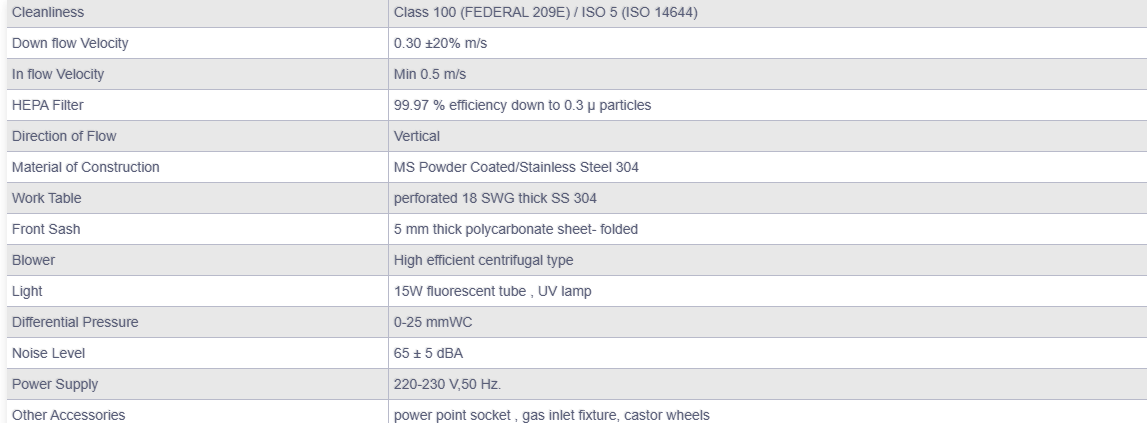

Typical Specifications :